A Snap Ring, also called a retaining ring or circlip, secures components onto a shaft or within a bore. It fits into a machined groove, preventing axial movement and keeping parts in place. Automotive, aerospace, and industrial applications widely use snap rings for their reliability, easy installation, and cost-effectiveness.

How Does a Snap Ring Work?

This is designed to snap into a pre-cut groove on a shaft or bore. When installed, it exerts radial force, ensuring that components remain securely positioned. There are two main types of snap rings:

- Internal Snap Rings – Installed inside a bore, pushing outward to hold a component in place.

- External Snap Rings – Fitted around a shaft, applying inward pressure to secure parts.

Where Are Snap Rings Used?

Rings are commonly found in:

- Automotive transmissions to retain bearings and gears.

- Aerospace components where secure fastening is crucial.

- Industrial machinery for securing rotating parts.

- Electronics such as printers and small mechanical devices.

Why Use a Snap Ring?

This ring is a preferred fastening solution due to its:

- Ease of installation – Quickly snaps into place without additional fasteners.

- Cost-effectiveness – Reducing machining and assembly costs.

- Space-saving design – Requires minimal space compared to bolts and nuts.

Read more: Men chat

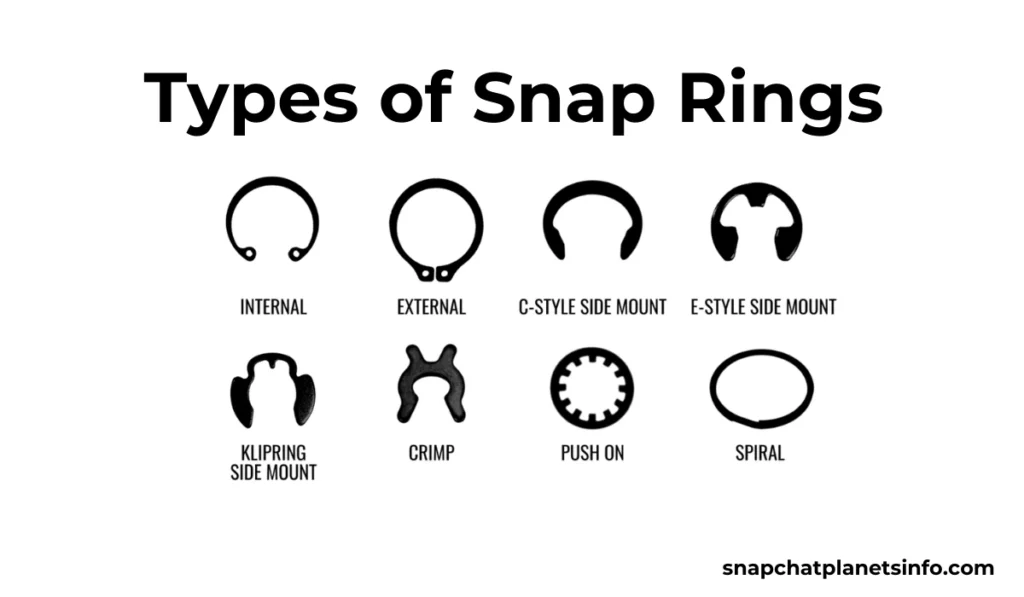

Types of Snap Rings

These rings are categorized based on their design and function. The two primary types are internal snap rings and external snap rings.

| Ring Type | Description | Application |

|---|---|---|

| Internal Snap Ring | Fits into a bore and exerts outward pressure to retain components. | Used inside housings, cylinders, or bearing assemblies. |

| External Snap Ring | Clips around a shaft and exerts inward pressure to hold parts. | Common in rotating shafts, gear assemblies, and pulleys. |

Each type comes in various styles, such as beveled rings, bowed rings, and E-clips, which provide different locking and load-bearing characteristics.

Materials Used in Snap Rings

The performance of a ring depends significantly on the material used in its construction. The choice of material affects strength, corrosion resistance, and durability.

| Material | Properties | Common Applications |

|---|---|---|

| Carbon Steel | High strength, durable, cost-effective | Automotive transmissions, industrial machinery |

| Stainless Steel | Corrosion-resistant, long lifespan | Marine equipment, food processing machinery |

| Beryllium Copper | Good electrical conductivity, fatigue-resistant | Aerospace, electrical connectors |

| Chrome Silicon | High-temperature resistance, excellent fatigue strength | Heavy-duty machinery, high-load applications |

Each material provides different benefits, making it essential to choose the right one for the intended application.

Advantages of Snap Rings Over Traditional Fasteners

This rings are widely used due to their many benefits compared to traditional fastening methods like bolts, screws, or pins.

| Feature | Snap Rings | Traditional Fasteners (Bolts/Screws) |

|---|---|---|

| Ease of Installation | Simple snap-on design, no threading required | Requires screwing or complex assembly |

| Weight and Space | Lightweight and compact | Bulkier and heavier |

| Cost-Effectiveness | Lower manufacturing and installation costs | Higher production and assembly costs |

| Reliability | Provides secure locking under vibration and stress | Can loosen over time due to movement |

Common Applications of Snap Rings

Rings are used in a variety of industries where securing parts without additional fasteners is necessary.

| Industry | Application |

|---|---|

| Automotive | Securing gears, bearings, and axles in transmissions |

| Aerospace | Used in jet engines, landing gear, and control systems |

| Industrial Machinery | Retaining components in heavy-duty rotating systems |

| Medical Equipment | Holding components in place in diagnostic machines |

Snap Ring Installation and Removal

Installing a ring correctly ensures that it functions effectively and prevents component failure. The use of ring pliers makes installation easier.

Installation Steps:

- Select the correct ring size for the shaft or bore.

- Use ring pliers to expand (for external rings) or compress (for internal rings).

- Carefully place the ring into the designated groove.

- Release the pliers to allow the ring to snap into position.

- Ensure the ring is securely seated in the groove.

Removal Steps:

- Use the pliers to grip the ends of the ring.

- Expand or compress the ring to remove it from the groove.

- Carefully pull the ring away from the shaft or bore.

- Store the ring properly if it is reusable.

Using the right tools and techniques prevents damage to the ring and ensures smooth removal.

Read more: Plain chat

Snap Ring Failures and How to Prevent Them

While snap rings are durable, they can fail if not used correctly. Understanding common failures helps in preventing mechanical issues.

| Failure Type | Cause | Prevention |

|---|---|---|

| Deformation | Overstretching or incorrect installation | Use the correct size and proper tools |

| Fatigue Failure | Repeated stress cycles leading to breakage | Select high-strength materials like chrome silicon |

| Corrosion | Exposure to moisture or chemicals | Use stainless steel or coated snap rings |

| Incorrect Fit | Using a ring that is too loose or too tight | Measure shaft/bore dimensions accurately |

Choosing the Right Snap Ring

To ensure the ring functions correctly, consider the following factors:

- Material Selection: Choose a material that suits the operating environment.

- Size & Dimensions: Measure the shaft or bore diameter precisely.

- Load Capacity: Ensure the ring can handle the expected force.

- Environmental Factors: Consider corrosion resistance if used in harsh conditions.

Proper selection extends the lifespan of the ring and enhances the reliability of the mechanical system.

Frequently Asked Questions

What is the purpose of a snap ring?

A snap ring is used to retain components on a shaft or inside a bore, preventing axial movement.

Can rings be reused?

While some snap rings can be reused, it is best to replace them after removal to ensure a secure fit.

What tools are needed to install a ring?

Special ring pliers are used to expand or compress the ring for proper installation.

How do I choose the right ring size?

Measure the shaft or bore diameter accurately and select a ring that fits securely into the designated groove.

Conclusion

A snap ring is a small but crucial component in mechanical systems. Its ability to securely hold parts in place while allowing easy assembly and maintenance makes it superior to traditional fasteners. Whether used in automotive, aerospace, or industrial applications, choosing the right ring based on material, size, and load requirements ensures long-term performance and reliability.

By selecting the correct snap ring, using proper tools, and ensuring correct installation, you can achieve a secure and efficient fastening solution in any mechanical system.