Snap Ring Pliers are essential tools used for installing and removing snap rings, also known as circlips or retaining rings. These small but powerful rings hold components securely on a shaft or inside a bore, making them crucial in machinery and mechanical applications. Without the right tool, handling snap rings can be a frustrating and time-consuming task. This article will provide detailed insights into snap ring pliers, their types, uses, and how to choose the best one for your needs.

Understanding Snap Ring Pliers

Snap ring pliers are specifically designed to grip and manipulate snap rings. Unlike standard pliers, these tools have specially shaped tips that fit into the holes of snap rings, allowing for easy expansion or compression. Ring plier come in different sizes and styles to accommodate various snap ring diameters and applications. Choosing the right pair ensures efficient and safe installation or removal of snap rings.

How Do Snap Ring Plier Work?

Snap ring pliers function by gripping the holes at the ends of a snap ring and either opening or closing it. The process depends on whether the snap ring is internal or external. External snap rings are found on shafts and must be expanded to fit over a groove. Internal snap rings, on the other hand, fit inside bores and require compression to install or remove.

The right ring pliers ensure a secure grip, preventing the ring from slipping and causing injury or damage. Professional mechanics, engineers, and DIY enthusiasts rely on these pliers for precise and hassle-free handling of snap rings.

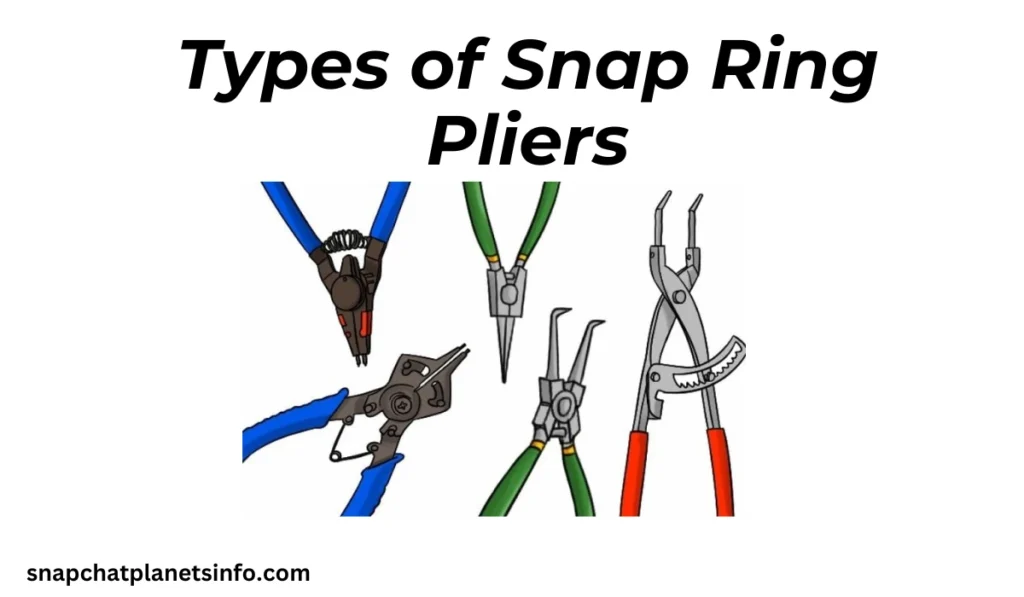

Types of Snap Ring Pliers

There are different types of snap ring plier, each designed for a specific function. Understanding these types helps in selecting the right tool for the job.

Internal Snap Ring Pliers

These pliers are used to install or remove Internal Snap Ring Pliers inside a bore. When the handles are squeezed, the tips close, compressing the ring for easy placement or removal.

External Ring Pliers

External snap rings fit around a shaft and must be expanded to remove or install. Ring pliers for external rings work by spreading the ring outward when pressure is applied.

Convertible Ring Pliers

Convertible ring pliers offer dual functionality, allowing users to switch between internal and external applications. These versatile tools are ideal for mechanics and professionals who frequently work with different snap rings.

Long Nose Ring Pliers

Designed for working in tight spaces, long nose ring pliers feature extended tips. These pliers provide better reach and control when installing or removing snap rings in deep or hard-to-reach areas.

Heavy-Duty Ring Pliers

For industrial applications and heavy machinery, heavy-duty ring pliers are the best choice. They are built with durable materials, ensuring strength and reliability when handling large or stubborn snap rings.

Read more: Group chat names for 3

Choosing the Right Snap Ring Pliers

Selecting the best snap ring plier depends on several factors, including the type of snap ring, size, and application. A good pair of pliers should be durable, easy to use, and comfortable to grip.

Key Considerations:

- Snap Ring Size: Ensure the pliers match the snap ring’s diameter.

- Type of Snap Ring: Choose internal or external pliers based on the application.

- Material: High-quality steel pliers last longer and provide better performance.

- Handle Comfort: Ergonomic grips reduce hand fatigue during extended use.

- Tip Style: Straight or angled tips should be chosen based on accessibility and application.

Using the right ring pliers enhances efficiency and prevents damage to components or injury to the user.

How to Use Snap Ring Plier

Using snap ring plier correctly ensures smooth installation and removal of snap rings. Here is a step-by-step guide:

Removing an External Snap Ring

- Insert the pliers’ tips into the holes of the snap ring.

- Squeeze the handles to expand the ring.

- Carefully lift the snap ring away from the shaft.

- Release the pliers once the snap ring is removed.

Installing an External Snap Ring

- Position the snap ring in the groove on the shaft.

- Use ring pliers to expand the ring.

- Place it carefully onto the shaft.

- Release the pliers, allowing the ring to snap into place.

Removing an Internal Snap Ring

- Insert the pliers’ tips into the snap ring’s holes.

- Squeeze the handles to compress the ring.

- Lift the snap ring out of the bore.

- Release the pliers once the ring is free.

Installing an Internal Snap Ring

- Position the snap ring inside the bore.

- Use snap ring plier to compress the ring.

- Place it in the groove.

- Release the pliers to allow the snap ring to expand into position.

Common Mistakes to Avoid

Many users make mistakes while using ring pliers, leading to tool damage or improper snap ring installation. Some common mistakes include:

- Using the wrong type of pliers for the snap ring.

- Applying too much force, which can break the snap ring.

- Not choosing the correct tip size, leading to a weak grip.

- Neglecting safety precautions, such as wearing protective gloves.

By avoiding these errors, users can ensure smooth operation and extended tool life.

Read more: Poly ai create ai chat bot

Snap Ring Plier Size Chart

| Snap Ring Diameter | Recommended Pliers Size |

|---|---|

| 0.5mm – 10mm | Mini Ring Pliers |

| 10mm – 50mm | Standard Ring Pliers |

| 50mm – 500mm | Heavy-Duty Ring Pliers |

| 500mm+ | Industrial Ring Pliers |

Frequently Asked Questions

What are snap ring pliers used for?

Snap ring plier are used to install and remove snap rings, which secure components on a shaft or inside a bore.

Can I use regular pliers instead of ring pliers?

No, regular pliers do not have the specialized tips needed to grip and manipulate snap rings effectively.

What is the difference between internal and external ring pliers?

Internal ring pliers compress snap rings for installation inside bores, while external pliers expand snap rings for placement on shafts.

How do I choose the right ring pliers?

Consider the size of the snap ring, the application (internal or external), and the accessibility of the installation area when selecting pliers.

Conclusion

Snap ring pliers are indispensable tools for handling snap rings efficiently. Whether for automotive repairs, machinery maintenance, or DIY projects, the right pair of pliers makes the job easier and safer. Selecting the appropriate type and size ensures precision and reliability. By understanding how to use these pliers correctly, users can avoid common mistakes and extend the lifespan of both the tool and the snap rings. Investing in high-quality snap ring pliers is a smart decision for anyone working with mechanical components.